Testing machine

Home > Products > Testing machine > Testing machine

Executive stand:

1、 technical data and enterprise standard offered by clients

2、 GB/T228 <mental material tension test at room temperature method>

3、 GB/T2611 <testing machine general technical requirements>

Structural description:

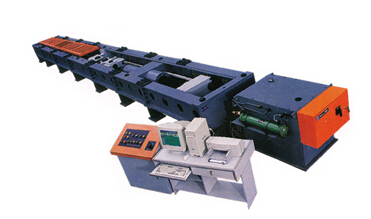

The system is composed of horizontal tensile testing machine mainframe、testing machine hydraulic station、sample support car、microcomputer process control and data automatic collection processing system、safety protection and alarm system.

1、 horizontal testing machine mainframe:

The body of testing machine mainframe adopted horizontal steel frame structure: hydraulic servo-cylinder installed on oil cylinder socket, the end region of the piston connected with moved cross beam through universal sphere and high precision force sensor. The moved cross beam then via double tie-bar and front strength seat formed loading mechanism. Moveable after-stretching seat moving forward and backward in left and right frame under the action of motor reducing gear. To reach the required place, Hydraulic cross-pin cylinder drive the cross-pin to make mobile chuck seat fixed on left and right frame, thereby to implement the setting adjustment of the distance of front and back stretch seat and to meet the test requirements for different length sample. The loading oil cylinder was under the action of hydraulic power, piston stretch out front stretch seat indirectly to implement loading for sample. The side of loading hydraulic cylinder installed displacement measurement device, which was used to measure oil cylinder stroke.

To meet the measurement of small load sample, the machine was equipped with 1000KNsmall load cell, which is convenient in tandem with stretch axis and also increase the test accuracy. The machine was equipped with stretch head for ostiole and plug-pin、small pin bush correspondingly. It can in tandem with large stretch head to meet small sample stretch.

Moveable high-low shield installed on top of the two sides of the frame(see figure2), then push the high-low shield above the sample after installed.